INVERTER DRIVE iZaII SERIES

With maximized freezing capacity combined with outstanding energy-saving performance in an unheard-of way, iZα series compressor condensing units are being highly acclaimed by customers. KOBELCO's unique theory and technology (patent acquired) that backed iZ and iZα series have received high praise in various industrial circles, being granted the Technology Award from the Japan Society of Refrigeration and Air Conditioning Engineers and the Japan Machinery Federation's Best Energy-saving Equipment Award.

Price: Contact

Description

| Download Brochure (3.45MB) |

Features

KOBELCO Screw Refrigeration Compressors Always Leading the Times

As a pioneer of screw refrigeration compressors, KOBELCO has taken the lead in the industrial all along, responding to customer's needs always with innovative ideas and proposals. As the new generational of conventional fixed speed drive model SH series, KOBELCO has developed iZ series in 2002, the world first Integral Two Stage Inverter Drive Freon Screw Compressor condensing units with higher cooling capacity than ever before. This series was followed in 2003 by iZα series of an epoch making non-ozone-depleting compressor condensing unit models using refrigerant R404A. iZαⅡ series is iZα series second generation equipped with "New iZ monitor"

With maximized freezing capacity combined with outstanding energy-saving performance in an unheard-of way, iZα series compressor condensing units are being highly acclaimed by customers. KOBELCO's unique theory and technology (patent acquired) that backed iZ and iZα series have received high praise in various industrial circles, being granted the Technology Award from the Japan Society of Refrigeration and Air Conditioning Engineers and the Japan Machinery Federation's Best Energy-saving Equipment Award.

We pursue untiring efforts towards development of earth-friendly products and continue being all attentions to our customer's voice so that we can offer such safe products that can be used with peace of mind while meeting the diversified needs of customers.

Refrigerant R404A does not deplete the OZONE layer.

Since the production of specified ozone-depleting HCFC-based refrigerants (R22) began to be sharply reduced in 2004 and will be completely banned in 2020, a prompt shift to non-ozone-depleting HFC refrigerants is required for compressor condensing units. With zero ozone depleting potential, R404A is a new, environment-friendly HFC refrigerant.

The new HFC refrigerant 404A is similar to the conventional HCFC refrigerant 22 in pressure property and easy to use.

| Refrigerant composition | ODP | Saturation pressure | Toxicity | Safety | |

|---|---|---|---|---|---|

| New HFC R404A |

Blended refrigerant (Pseudo-azeotropic mixture) (HFC125: 143a: 134a=44: 52: 4 wt%) |

zero | 2.3MPa | Non-toxic | ○ |

| Conventional HCFC R22 |

Non-blended refrigerant(100 wt%) | 0.055 | 1.9MPa | Non-toxic | ○ |

* The above saturation pressure values are measured at standard condensation temperature of 50°C.

Kobelco's five big features.

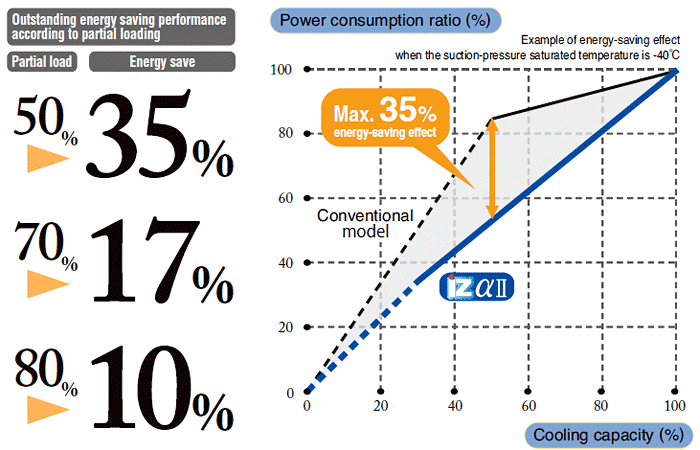

1. Outstanding energy saving performance by Kobelco inverter drive compressor.

iZαⅡ series can control its cooling capacity with its inverter drive linear speed control to avoid excessive cooling, thereby permitting outstanding energy saving performance.

Piston valve used for capacity control has been replaced to inverter drive capacity control to ensure optimum operation in accordance with cooling capacity fluctuation.

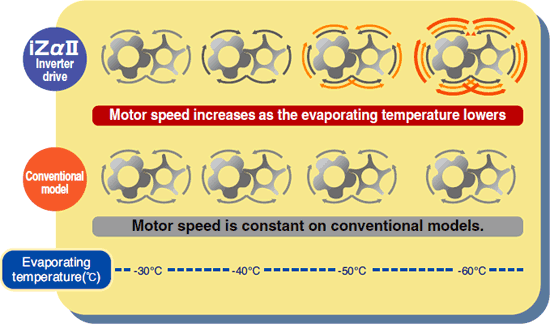

2. Maximum 40% increasable cooling capacity by accelerating rotating speed by inverter drive

(compared with Kobelco conventional model in 50Hz area)

Conventional refrigeration compressor has been unavoidable to reduce cooling capacity significantly accompany with evaporating temperature drops. Accelerating motor speed technology with inverter drive (Patent registered) enable iZαⅡ series increase its cooling capacity at lower temperature than -30°C .

iZαⅡ series can perform equally in both of 50Hz and 60Hz area, which is a big merit for 50Hz area users where 20% less performance than 60Hz area has been unavoidable. Those functions enable to select smaller compressor than before.

iZαⅡ Series motor speed accelerates accompany with evaporative temperature drop.

3. "New iZ monitor" with various function for quick and advance trouble shooting.

New iZ monitor indicates compressor running conditions, various alarms and those histories. Also stops compressor automatically against emergency waning.

- Alternative running applications

Alternative linear capacity control or step capacity control can be selected due to clients demands. - Suction pressure / Remote temperature capacity control

Linear capacity control with originally equipped suction pressure sensor and also optionally installed temperature sensor (requested users to supply) at freezing site are available. - Additional indication

Super heat is added to monitor compressor situation more clearly. - Linear capacity control

Inverter fixes its rotating speed sensing with originally equipped suction pressure sensor otherwise optionally equipped temperature sensor (the sensor and 4-20mA DC signal are requested users to supply) at freezing site. Controlling factor of suction pressure at the freezing site is requested to preset. - Step control

Capacity step control function is also equipped with iZ monitor, its setting value is available to change flexibly.

Compressor protective functions:

- Discharge temperature

- Oil pressure differential

- Discharge pressure

- Over current

- Motor temperature

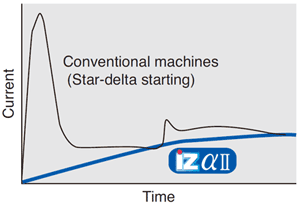

4. Merits of motor start up by inverter drive

Smooth motor startup by inveter drive eliminates inrush current and hot start

The effect of equipped inverter drive can be found when to startup compressor. Since conventional star-delta startup induces inrush current and requires approx 10 minutes interval before restarting. Thanks to the equipped inverter that allows smooth starting, iZαⅡ series can restart quickly without any interval. The smooth starting mechanism permits compressor to stop even in the conventional condition of interruption is not allowed. This mechanism enables more effective energy saving and down sizing of the power facility.

5. Multiple effects created by economizer and inverter drive harmony

iZαⅡ series is equipped economizer regularly and controlled rotating speed of its 1st and 2nd stage by inverter drive. If 1st and 2nd stages do not change their rotating speed at once properly economizer cannot perform properly because pressure unbalance among 1st, middle and 2nd stage caused. iZαⅡ series can control rotating speed flexibly and perfectly always to supply the best performance.

Specification

Water-cooled Standard Specifications (-30°C to -65°C)

|

Unit type Item |

iZα30WⅡ | iZα40WⅡ | iZα50WⅡ | iZα70WⅡ | iZα80WⅡ | iZα90WⅡ | iZα110WⅡ | ||

|---|---|---|---|---|---|---|---|---|---|

| Frequency | 50/60Hz | ||||||||

| Legal ton of refrigeration (JRT) | 7.07 | 9.90 | 12.17 | 12.22 | 15.37 | 16.95 | 20.47 | ||

| Refrigerant | R404A | ||||||||

| Power source | Motor: 200/220/380/400/415/440/460/480, 3 phase. 50/60Hz, Control circuit: 200 to 230V, 1 phase, 50/60Hz | ||||||||

| Number of compressors | 1 Unit | ||||||||

| Capacity control *1*2*3 | Continuous control mode or step control mode (3 steps: 50%, 75% and 100%) | ||||||||

| Motor | Nominal output kW | 18 | 24 | 30 | 37 | 45 | 55 | 65 | |

| Type | Water-cooled semi-hermetic; 4-pole; 3-phase induction type | ||||||||

| Starting method | Inverter | ||||||||

| Condenser | Type | Horizontal shell and tube (serving also as a receiver) | |||||||

| Receiver capacity ℓ | 35 | 35 | 35 | 58 | 161 | 76 | 76 | ||

| Refrigerant spatial volume ℓ*4 | 91 | 91 | 89 | 145 | 231 | 220 | 220 | ||

| Connections | Refrigerant gas inlet | 50A | 50A | 50A | 80A | 80A | 80A | 100A | |

| Refrigerant liquid outlet | 19.05mm | 25.4mm | 25.4mm | 31.8mm | 31.8mm | 31.8mm | 34.9mm | ||

| Cooling water inlet/outlet | Condenser | Rc2 | Rc2 | Rc2 | Rc3 | Rc3 | Rc3 | Rc3 | |

| Oil cooler | Oil coolerless specification | Rc1 | Rc1 | Rc1 | Rc1 | ||||

| Motor | Rc1 | Rc1 | Rc1 | Rc1 | Rc1 | Rc1 | Rc1 | ||

| Lubricating oil ℓ*5 | 10 | 10 | 13 | 14 | 21 | 22 | 29 | ||

| Noise dB(A)*6 | 71 | 73 | 75 | 75 | 75 | 79 | 78 | ||

| Dimensions W x D x H mm |

1380 x 1110 x 1320 |

1380 x 1110 x 1320 |

1405 x 1150 x 1365 |

1675 x 1200 x 1425 |

2490 x 1265 x 1525 |

2485 x 1260 x 1555 |

2485 x 1290 x 1560 |

||

| Weight kg | 825 | 840 | 885 | 1245 | 1460 | 1485 | 1825 | ||

|

Unit type Item |

iZα140WⅡ | iZα160WⅡ | iZα180WⅡ | iZα220WⅡ | iZα280WⅡ | iZα320WⅡ | ||

|---|---|---|---|---|---|---|---|---|

| Frequency | 50/60Hz | |||||||

| Legal ton of refrigeration (JRT) | 24.90 | 29.34 | 33.90 | 40.94 | 49.80 | 58.68 | ||

| Refrigerant | R404A | |||||||

| Power source | Motor: 200/220/380/400/415/440/460/480, 3 phase, 50/60Hz, Control circuit: 200 - 230V, 1 phase, 50/60Hz | |||||||

| Number of compressors | 1 Unit | 2 Units | ||||||

| Capacity control *1*2*3 | Continuous control mode or step control mode (3 steps: 50%, 75% and 100%) | |||||||

| Motor | Nominal output kW | 75 | 90 | 55 x 2 | 65 x 2 | 75 x 2 | 90 x 2 | |

| Type | Water-cooled semi-hermetic; 4-pole; 3-phase induction type | |||||||

| Starting method | Inverter | |||||||

| Condenser | Type | Horizontal shell and tube (serving also as a receiver) | ||||||

| Receiver capacity ℓ | 183 | 183 | 278 | 278 | 398 | 398 | ||

| Refrigerant spatial volume ℓ*4 | 278 | 278 | 434 | 434 | 562 | 562 | ||

| Connections | Refrigerant gas inlet | 100A | 100A | 80A x 2 | 100A x 2 | 100A x 2 | 100A x 2 | |

| Refrigerant liquid outlet | 38.1mm | 38.1mm | 40A | 40A | 50A | 50A | ||

| Cooling water inlet/outlet | Condenser | Rc3 | Rc3 | Rc4 | Rc4 | 150A | 150A | |

| Oil cooler | Rc1 | Rc1 | Rc1 x 2 | Rc1 x 2 | Rc1 x 2 | Rc1 x 2 | ||

| Motor | Rc1 | Rc1 | Rc1 x 2 | Rc1 x 2 | Rc1 x 2 | Rc1 x 2 | ||

| Lubricating oil ℓ*5 | 29 | 53 | 53 | 60 | 84 | 84 | ||

| Noise dB(A)*6 | 79 | 82 | 82 | 81 | 82 | 85 | ||

| Dimensions W x D x H mm | 3000 x 1320 x 1720 |

3000 x 1420 x 1765 |

3025 x 1970 x 1750 |

3025 x 2055 x 1790 |

2960 x 2140 x 1890 |

2960 x 2140 x 1890 |

||

| Weight kg | 1930 | 2020 | 2710 | 3300 | 4380 | 4440 | ||

*1: The minimum capacity depends on production range and operation conditions (25%-50%)

*2: Requested to enter proper signal due to selected running mode.

*3: Partial loading value for step control is changeable flexibly.

*4. Condenser spatial volume for refrigerant is calculated by subtracting the volume of the heat exchanger tube from the inside volume of the condenser.

*5: Oil quantity is minimum charge only for condensing unit. Actual oil quantity for whole of the plant (system) should be determined at the site referring the oil level of sight glasses during compressor running. Charge oil on site and replenish when the level gets lower than requested. Use specified refrigerant machine oil (Oil is requested users to supply)

*6: Noise level (scale A) indicates the values measured at 1meter away from the compressor and 1meter above from the floor level when the suction pressure saturated temperature is -40°Cwithout any echo influence. In the actual installed conditions the noise level maybe different from indicated value because of the influence of surrounding noise and echo.

* : Hot gas defrost model is available optionally.

* : When suction pressure saturated temperature is required below -50°Cmodification for ultra low temperature with cost up is needed.

* : Noise control and harmonic suppression measurement should be taken as necessary according to respective guidelines.

* : Electric power for control circuit is requested users to supply.

Cooling capacity (kW)

Refrigerant: R404A

| Condensing temperature °C |

Saturated temp. at suction press. °C |

iZα 30WⅡ |

iZα 40WⅡ |

iZα 50WⅡ |

iZα 70WⅡ |

iZα 80WⅡ |

iZα 90WⅡ |

iZα 110WⅡ |

iZα 140WⅡ |

iZα 160WⅡ |

iZα 180WⅡ |

iZα 220WⅡ |

iZα 280WⅡ |

iZα 320WⅡ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 35 | -30 | 37.1 | 53.3 | 67.1 | 77.0 | 97.4 | 107.9 | 128.1 | 159.0 | 185.6 | 215.8 | 256.2 | 318.0 | 371.2 |

| -35 | 34.5 | 49.2 | 62.1 | 71.0 | 90.0 | 99.9 | 118.1 | 146.7 | 171.4 | 199.8 | 236.2 | 293.4 | 342.8 | |

| -40 | 31.3 | 44.9 | 56.6 | 63.3 | 80.3 | 89.0 | 105.5 | 131.3 | 153.2 | 178.0 | 211.0 | 262.6 | 306.4 | |

| -45 | 27.1 | 39.1 | 49.3 | 54.8 | 69.6 | 77.0 | 91.7 | 113.8 | 133.1 | 154.0 | 183.4 | 227.6 | 266.2 | |

| -50 | 22.5 | 32.8 | 41.1 | 45.9 | 58.5 | 64.6 | 77.2 | 96.3 | 112.1 | 129.2 | 154.4 | 192.6 | 224.2 | |

| -55 | 18.3 | 27.3 | 34.3 | 37.5 | 47.7 | 52.7 | 63.4 | 79.0 | 92.0 | 105.4 | 126.8 | 158.0 | 184.0 | |

| -60 | 14.3 | 21.9 | 27.3 | 29.9 | 38.0 | 42.0 | 51.1 | 63.6 | 74.2 | 84.0 | 102.2 | 127.2 | 148.4 | |

| -65 | 10.9 | 17.2 | 21.7 | 23.2 | 29.6 | 32.3 | 40.2 | 50.1 | 57.7 | 64.6 | 80.4 | 100.2 | 115.4 | |

| 40 | -30 | 36.5 | 52.6 | 66.2 | 75.8 | 96.2 | 106.4 | 126.1 | 156.3 | 182.7 | 212.8 | 252.2 | 312.6 | 365.4 |

| -35 | 33.9 | 48.5 | 61.1 | 69.9 | 88.7 | 98.3 | 116.2 | 144.5 | 169.0 | 196.6 | 232.4 | 289.0 | 338.0 | |

| -40 | 30.5 | 43.7 | 55.1 | 61.6 | 78.2 | 86.6 | 102.8 | 127.8 | 149.5 | 173.2 | 205.6 | 255.6 | 299.0 | |

| -45 | 26.3 | 38.0 | 47.9 | 53.2 | 67.6 | 74.8 | 89.2 | 110.8 | 129.6 | 149.6 | 178.4 | 221.6 | 259.2 | |

| -50 | 21.9 | 31.9 | 39.9 | 44.6 | 56.7 | 62.7 | 75.3 | 93.5 | 109.1 | 125.4 | 150.6 | 187.0 | 218.2 | |

| -55 | 17.7 | 26.4 | 33.2 | 36.2 | 46.2 | 51.0 | 61.6 | 76.6 | 89.2 | 102.0 | 123.2 | 153.2 | 178.4 | |

| -60 | 13.8 | 21.1 | 26.4 | 28.9 | 36.7 | 40.5 | 49.5 | 61.7 | 71.8 | 81.0 | 99.0 | 123.4 | 143.6 | |

| -65 | 10.5 | 16.4 | 20.7 | 22.2 | 28.2 | 30.9 | 38.8 | 48.3 | 55.6 | 61.8 | 77.6 | 96.6 | 111.2 |

* : This is the case for superheat 0°C and economizer middle stage evaporative temperature +10°C (iZα30WⅡ, 40WⅡ, 50WⅡ case is +5°C)

* : Please contact Kobelco in case of using suction pressure saturating temperature is less than -50°C

Power consumption (kW)

| Condensing temperature °C |

Saturated temp. at suction press. °C |

iZα 30WⅡ |

iZα 40WⅡ |

iZα 50WⅡ |

iZα 70WⅡ |

iZα 80WⅡ |

iZα 90WⅡ |

iZα 110WⅡ |

iZα 140WⅡ |

iZα 160WⅡ |

iZα 180WⅡ |

iZα 220WⅡ |

iZα 280WⅡ |

iZα 320WⅡ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 35 | -30 | 21.2 | 28.1 | 32.9 | 40.3 | 50.2 | 55.3 | 66.8 | 82.4 | 94.9 | 110.6 | 133.6 | 164.8 | 189.8 |

| -35 | 22.2 | 30.2 | 34.2 | 41.0 | 51.2 | 56.2 | 68.0 | 83.8 | 97.4 | 112.4 | 136.0 | 167.6 | 194.8 | |

| -40 | 22.3 | 29.9 | 35.0 | 40.5 | 50.5 | 55.7 | 67.9 | 84.5 | 98.9 | 111.4 | 135.8 | 169.0 | 197.8 | |

| -45 | 22.7 | 30.4 | 34.8 | 40.3 | 50.0 | 55.4 | 67.7 | 83.9 | 98.5 | 110.8 | 135.4 | 167.8 | 197.0 | |

| -50 | 22.0 | 29.0 | 34.0 | 38.6 | 48.6 | 53.6 | 66.7 | 82.5 | 96.7 | 107.2 | 133.4 | 165.0 | 193.4 | |

| -55 | 22.2 | 29.0 | 34.3 | 37.2 | 46.7 | 51.5 | 65.6 | 80.0 | 93.5 | 103.0 | 131.2 | 160.0 | 187.0 | |

| -60 | 21.4 | 27.7 | 31.7 | 36.1 | 45.2 | 49.8 | 63.8 | 77.5 | 90.3 | 99.6 | 127.6 | 155.0 | 180.6 | |

| -65 | 21.5 | 27.7 | 30.0 | 34.6 | 42.8 | 46.9 | 61.5 | 75.2 | 86.0 | 93.8 | 123.0 | 150.4 | 172.0 | |

| 40 | -30 | 22.6 | 30.3 | 35.0 | 43.0 | 54.1 | 58.8 | 69.7 | 86.0 | 100.6 | 117.6 | 139.4 | 172.0 | 201.2 |

| -35 | 23.8 | 32.1 | 36.3 | 43.9 | 54.3 | 59.7 | 70.7 | 88.2 | 102.5 | 119.4 | 141.4 | 176.4 | 205.0 | |

| -40 | 23.9 | 31.9 | 37.1 | 43.5 | 53.8 | 59.1 | 71.6 | 89.0 | 104.4 | 118.2 | 143.2 | 178.0 | 208.8 | |

| -45 | 24.5 | 32.7 | 37.2 | 43.4 | 53.2 | 58.5 | 71.1 | 88.2 | 103.9 | 117.0 | 142.2 | 176.4 | 207.8 | |

| -50 | 23.7 | 31.1 | 36.2 | 41.5 | 52.0 | 57.0 | 70.3 | 86.7 | 101.7 | 114.0 | 140.6 | 173.4 | 203.4 | |

| -55 | 23.9 | 31.4 | 36.7 | 40.1 | 49.5 | 55.1 | 69.1 | 83.9 | 98.2 | 110.2 | 138.2 | 167.8 | 196.4 | |

| -60 | 23.1 | 29.6 | 34.3 | 38.9 | 48.3 | 53.8 | 67.4 | 81.8 | 95.0 | 107.6 | 134.8 | 163.6 | 190.0 | |

| -65 | 23.2 | 29.8 | 32.4 | 37.4 | 46.1 | 50.6 | 65.0 | 79.5 | 91.0 | 101.2 | 130.0 | 159.0 | 182.0 |

Air-Cooled Standard Specifications (-30°C to -65°C)

Package-Type

|

Unit type Item |

iZα30AⅡ | iZα40AⅡ | iZα50AⅡ | iZα70AⅡ | iZα90AⅡ | ||

|---|---|---|---|---|---|---|---|

| Frequency | 50/60Hz | ||||||

| Legal ton of refrigeration (JRT) | 7.07 | 9.90 | 12.17 | 12.22 | 17.0 | ||

| Refrigerant | R404A | ||||||

| Power source | Motor: 200/220/380/400/415/440/460/480, 3 phase, 50/60Hz, Control circuit: 200 - 230V, 1 phase, 50/60Hz | ||||||

| Number of compressors | 1 Unit | ||||||

| Capacity control *1*2*3 | Continuous control mode or step control mode (3 steps: 50%, 75% and 100%) | ||||||

| Motor | Nominal output kW | 18 | 24 | 30 | 37 | 55 | |

| Type | Semi-hermetic; 4-pole; 3-phase induction type | ||||||

| Starting method | Inverter | ||||||

| Condenser | Type | Plate fin tube | |||||

| Air blower output kW x units | 0.4 x 2 | 0.4 x 3 | 0.75 x 3 | 0.2 x 6 | 0.4 x 6 | ||

| Receiver capacity ℓ | 76 | 109 | 109 | 177 | 235 | ||

| Lubricating oil ℓ*4 | 10.0 | 10 | 13 | 13 | 19 | ||

| Connections | Refrigerant gas inlet | 50.8mm | 50.8mm | 50.8mm | 63.5mm | 79.4mm | |

| Refrigerant liquid outlet | 19.05mm | 25.4mm | 25.4mm | 31.8mm | 31.8mm | ||

| Installation | Outdoor | ||||||

| Noise dB(A)*5 | 2055 x 1315 x 2255 |

2865 x 1315 x 2430 |

2865 x 1315 x 2430 |

2690 x 1395 x 2705 |

2690 x 1795 x 2805 |

||

| Dimensions W x D x H mm | 64 | 65 | 67 | 66 | 70 | ||

| Weight kg | 1400 | 1635 | 1700 | 2025 | 2330 | ||

Separate-type

|

Unit type Item |

iZα 30ASⅡ |

iZα 40ASⅡ |

iZα 50ASⅡ |

iZα 70ASⅡ |

iZα 90ASⅡ |

iZα 140ASⅡ |

iZα 180ASⅡ |

iZα 280ASⅡ |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Frequency | 50/60Hz | ||||||||||

| Legal ton of refrigeration (JRT) | 7.07 | 9.90 | 12.17 | 12.22 | 16.95 | 24.90 | 33.90 | 49.80 | |||

| Refrigerant | R404A | ||||||||||

| Power source | Motor: 200/220/380/400/415/440/460/480, 3 phase, 50/60Hz, Control circuit: 200 - 230V, 1 phase, 50/60Hz | ||||||||||

| Compressor unit | Number of compressors | 1 Unit | 2 Units | ||||||||

| Capacity control *1*2*3 | Continuous control mode or step control mode (3 steps: 50%, 75% and 100%) | ||||||||||

| Motor | Nominal output kW | 18 | 24 | 30 | 37 | 55 | 75 | 55 x 2 | 75 x 2 | ||

| Type | Semi-hermetic; 4-pole; 3-phase induction type | ||||||||||

| Starting method | Inverter | ||||||||||

| Receiver capacity ℓ | 76 | 109 | 109 | 177 | 265 | 380 | 504 | 599 | |||

| Lubricating oil ℓ*4 | 10 | 10 | 13 | 13 | 19 | 25 | 47 | 75 | |||

| Connections | Refrigerant gas inlet (suction) | 50A | 50A | 50A | 80A | 80A | 100A | 80A x 2 | 100A x 2 | ||

| Refrigerant liquid outlet (discharge) | 25A | 25A | 32A | 32A | 40A | 50A | 65A | 80A | |||

| Refrigerant liquid inlet (return) | 25.4mm | 31.8mm | 31.8mm | 38.1mm | 38.1mm | 50A | 65A | 80A | |||

| Refrigerant liquid outlet | 19.05mm | 25.4mm | 25.4mm | 31.8mm | 31.8mm | 38.1mm | 40A | 50A | |||

| Installation | Indoor | ||||||||||

| Dimensions W x D x H mm |

1645 x 1080 x 1125 |

2235 x 1125 x 1245 |

2235 x 1160 x 1245 |

2040 x 1195 x 1415 |

2300 x 1260 x 1415 |

3105 x 1300 x 1720 |

2810 x 1970 x 1645 |

3300 x 2140 x 1855 |

|||

| Noise dB(A)*5 | 71 | 73 | 75 | 75 | 79 | 79 | 82 | 82 | |||

| Weight kg | 795 | 830 | 895 | 1055 | 1170 | 1560 | 2210 | 3280 | |||

| Condenser unit |

Type x units | VACK24 | VACK32 | VACK40 | WACK50 | WACK75 | WACK50 x 2units |

WACK75 x 2units |

WACK50 x 4units |

||

| Air blower output KW x units | 0.4 x 2 | 0.4 x 3 | 0.75 x 3 | 0.2 x 6 | 0.4 x 6 | 0.2 x 6 2units |

0.4 x 6 2units |

0.2 x 6 4units |

|||

| Installation | Outdoor | ||||||||||

| Dimensions W x D x H mm |

2085 x 875 x 1175 |

2845 x 875 x 1175 |

2845 x 875 x 1175 |

2670 x 1220 x 1080 |

2670 x 1620 x 1185 |

2670 x 1220 x 1080 2units |

2670 x 1620 x 1185 2units |

2670 x 1220 x 1080 4units |

|||

| Noise dB(A)*5 | 63 | 65 | 66 | 65 | 67 | 68 | 70 | 71 | |||

| Weight kg | 250 | 340 | 370 | 500 | 530 | 500 2units |

530 2units |

500 4units |

|||

*1: The minimum capacity depends on production range and operation conditions (25%-50%)

*2: Requested to enter proper signal due to selected running mode.

*3: Partial loading value for step control is changeable flexibly.

*4. Condenser spatial volume for refrigerant is calculated by subtracting the volume of the heat exchanger tube from the inside volume of the condenser.

*5: Oil quantity is minimum charge only for condensing unit. Actual oil quantity for whole of the plant (system) should be determined at the site referring the oil level of sight glasses during compressor running. Charge oil on site and replenish when the level gets lower than requested. Use specified refrigerant machine oil (Oil is requested users to supply)

*6: Noise level (scale A) indicates the values measured at 1meter away from the compressor and 1meter above from the floor level when the suction pressure saturated temperature is -40°Cwithout any echo influence. In the actual installed conditions the noise level maybe different from indicated value because of the influence of surrounding noise and echo.

* : Hot gas defrost model is available optionally.

* : When suction pressure saturated temperature is required below -50°Cmodification for ultra low temperature with cost up is needed.

* : Noise control and harmonic suppression measurement should be taken as necessary according to respective guidelines.

* : Electric power for control circuit is requested users to supply.

Cooling capacity (kW)

Refrigerant: R404A

| Ambient temperature °C |

Saturated temp. at suction press. °C |

iZα 30AⅡ iZα 30ASⅡ |

iZα 40AⅡ iZα 40ASⅡ |

iZα 50AⅡ iZα 50ASⅡ |

iZα 70AⅡ iZα 70ASⅡ |

iZα 90AⅡ iZα 90ASⅡ |

iZα 140ASⅡ |

iZα 180ASⅡ |

iZα 280ASⅡ |

|---|---|---|---|---|---|---|---|---|---|

| 27 | -30 | 35.7 | 50.0 | 62.4 | 68.1 | 95.3 | 140.5 | 190.6 | 281.0 |

| -35 | 32.9 | 46.3 | 57.4 | 64.8 | 91.0 | 134.0 | 182.0 | 268.0 | |

| -40 | 29.6 | 41.8 | 51.9 | 59.4 | 83.8 | 123.4 | 167.6 | 246.8 | |

| -45 | 25.7 | 36.3 | 44.9 | 51.5 | 72.4 | 107.3 | 144.8 | 214.6 | |

| -50 | 21.7 | 30.7 | 37.9 | 43.4 | 61.0 | 90.8 | 122.0 | 181.6 | |

| -55 | 17.5 | 24.9 | 30.8 | 35.2 | 49.4 | 74.2 | 98.8 | 148.4 | |

| -60 | 13.9 | 19.8 | 24.8 | 27.9 | 39.3 | 59.4 | 78.6 | 118.8 | |

| -65 | 11.0 | 15.6 | 19.0 | 21.3 | 29.6 | 45.8 | 59.2 | 91.6 | |

| 32 | -30 | 34.2 | 48.0 | 59.7 | 66.1 | 92.4 | 135.9 | 184.8 | 271.8 |

| -35 | 32.0 | 45.0 | 55.9 | 62.9 | 88.1 | 130.1 | 176.2 | 260.2 | |

| -40 | 28.7 | 40.6 | 50.3 | 57.8 | 81.1 | 119.9 | 162.2 | 239.8 | |

| -45 | 25.0 | 35.3 | 43.6 | 50.1 | 70.3 | 104.4 | 140.6 | 208.8 | |

| -50 | 21.0 | 29.6 | 36.6 | 42.0 | 59.0 | 88.4 | 118.0 | 176.8 | |

| -55 | 17.1 | 24.2 | 29.9 | 34.0 | 47.7 | 71.9 | 95.4 | 143.8 | |

| -60 | 13.5 | 19.0 | 23.5 | 26.3 | 37.0 | 56.2 | 74.0 | 112.4 | |

| -65 | 10.4 | 14.7 | 17.9 | 19.8 | 27.6 | 43.2 | 55.2 | 86.4 |

* : This is the case for superheat 0°C and economizer middle stage evaporative temperature +10°C (iZα30WⅡ, 40WⅡ, 50WⅡ case is +5°C)

* : Please contact Kobelco in case of using suction pressure saturating temperature is less than -50°C

Power consumption (kW)

| Ambient temperature °C |

Saturated temp. at suction press. °C |

iZα 30AⅡ iZα 30ASⅡ |

iZα 40AⅡ iZα 40ASⅡ |

iZα 50AⅡ iZα 50ASⅡ |

iZα 70AⅡ iZα 70ASⅡ |

iZα 90AⅡ iZα 90ASⅡ |

iZα 140ASⅡ |

iZα 180ASⅡ |

iZα 280ASⅡ |

|---|---|---|---|---|---|---|---|---|---|

| 27 | -30 | 23.8 | 33.3 | 38.7 | 44.1 | 62.8 | 89.7 | 125.6 | 179.4 |

| -35 | 23.8 | 33.3 | 39.0 | 45.2 | 64.4 | 92.4 | 128.8 | 184.8 | |

| -40 | 23.8 | 33.1 | 38.9 | 45.2 | 64.2 | 92.8 | 128.4 | 185.6 | |

| -45 | 23.3 | 32.3 | 38.1 | 44.2 | 63.0 | 90.3 | 126.0 | 180.6 | |

| -50 | 22.7 | 31.5 | 37.1 | 42.8 | 61.0 | 87.5 | 122.0 | 175.0 | |

| -55 | 22.3 | 31.0 | 36.0 | 41.1 | 58.2 | 84.6 | 116.4 | 169.2 | |

| -60 | 21.8 | 30.1 | 34.9 | 39.0 | 55.7 | 80.9 | 111.4 | 161.8 | |

| -65 | 20.2 | 27.8 | 32.7 | 37.5 | 51.8 | 76.6 | 103.6 | 153.2 | |

| 32 | -30 | 25.3 | 35.3 | 41.3 | 47.7 | 68.2 | 97.4 | 136.4 | 194.8 |

| -35 | 25.3 | 35.4 | 41.4 | 49.3 | 70.2 | 100.3 | 140.4 | 200.6 | |

| -40 | 25.3 | 35.2 | 41.3 | 49.0 | 69.9 | 100.3 | 139.8 | 200.6 | |

| -45 | 25.2 | 34.9 | 41.1 | 48.2 | 68.6 | 98.6 | 137.2 | 197.2 | |

| -50 | 24.6 | 34.1 | 40.1 | 46.8 | 66.2 | 95.9 | 132.4 | 191.8 | |

| -55 | 24.3 | 33.6 | 39.6 | 45.0 | 63.7 | 91.9 | 127.4 | 183.8 | |

| -60 | 23.7 | 32.8 | 38.8 | 42.9 | 60.9 | 87.9 | 121.8 | 175.8 | |

| -65 | 22.1 | 30.5 | 35.8 | 41.2 | 56.6 | 83.1 | 113.2 | 166.2 |

* : Power consumption of condensing fan in not included.

-

Benefits of buying Kobelco compressors .

✓ Kobelco air compressor made in japan, full CO,CQ

✓ Experiened maintenance team.

✓ Spare part are always available.

✓ Free consultation: 0931205105